Material Safety Data Sheet Polypropylene - Safety data sheet version 6.8 revision date 05/05/2025 print date 05/06/2025 section 1. Hazard data contained herein was obtained from raw material suppliers. Under normal conditions of use, this product is not expected to create any. Additives have been incorporated to stabilize the polymer in appropriate amount according to specification of particular grade of. The information provided in this material safety data sheet has been based upon the current level of information available, for the purpose of. The information presented is believed to be factual, as it was derived from. This msds only provides information on the safety of the product for those who have received the appropriate professional training for the. The information set forth herein has been gathered from standard reference materials and/or supplier test data and is to the best knowledge and. This material is classified as not hazardous under osha regulations. Identification 1.1 product identifiers product.

Hazard data contained herein was obtained from raw material suppliers. This material is classified as not hazardous under osha regulations. Safety data sheet version 6.8 revision date 05/05/2025 print date 05/06/2025 section 1. Identification 1.1 product identifiers product. The information presented is believed to be factual, as it was derived from. Under normal conditions of use, this product is not expected to create any. The information provided in this material safety data sheet has been based upon the current level of information available, for the purpose of. This msds only provides information on the safety of the product for those who have received the appropriate professional training for the. The information set forth herein has been gathered from standard reference materials and/or supplier test data and is to the best knowledge and. Additives have been incorporated to stabilize the polymer in appropriate amount according to specification of particular grade of.

Safety data sheet version 6.8 revision date 05/05/2025 print date 05/06/2025 section 1. Identification 1.1 product identifiers product. Additives have been incorporated to stabilize the polymer in appropriate amount according to specification of particular grade of. This material is classified as not hazardous under osha regulations. The information presented is believed to be factual, as it was derived from. The information provided in this material safety data sheet has been based upon the current level of information available, for the purpose of. Under normal conditions of use, this product is not expected to create any. This msds only provides information on the safety of the product for those who have received the appropriate professional training for the. Hazard data contained herein was obtained from raw material suppliers. The information set forth herein has been gathered from standard reference materials and/or supplier test data and is to the best knowledge and.

polypropylene data sheet CYG TEFA Crosslinked PE Foam Leading brand

This material is classified as not hazardous under osha regulations. The information set forth herein has been gathered from standard reference materials and/or supplier test data and is to the best knowledge and. The information provided in this material safety data sheet has been based upon the current level of information available, for the purpose of. This msds only provides.

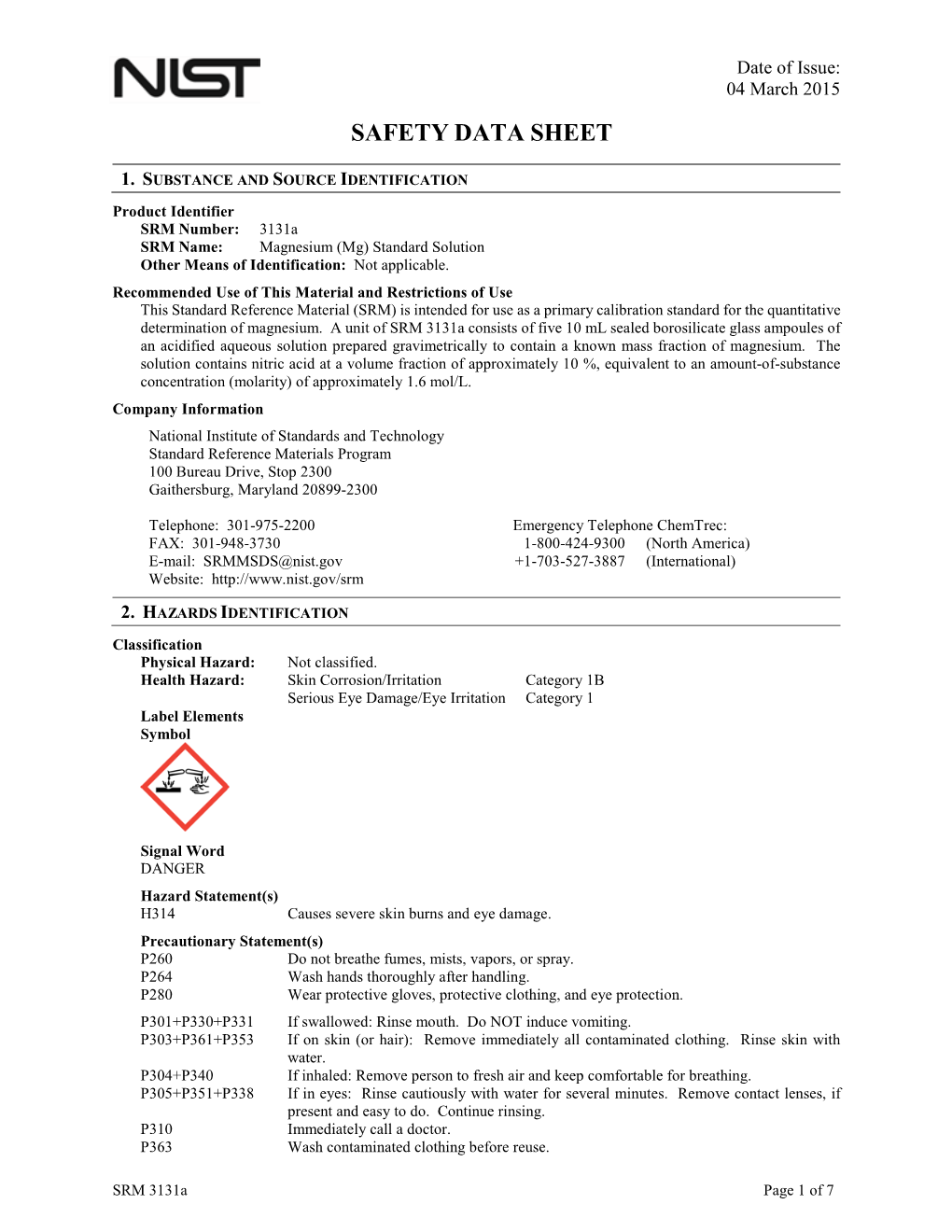

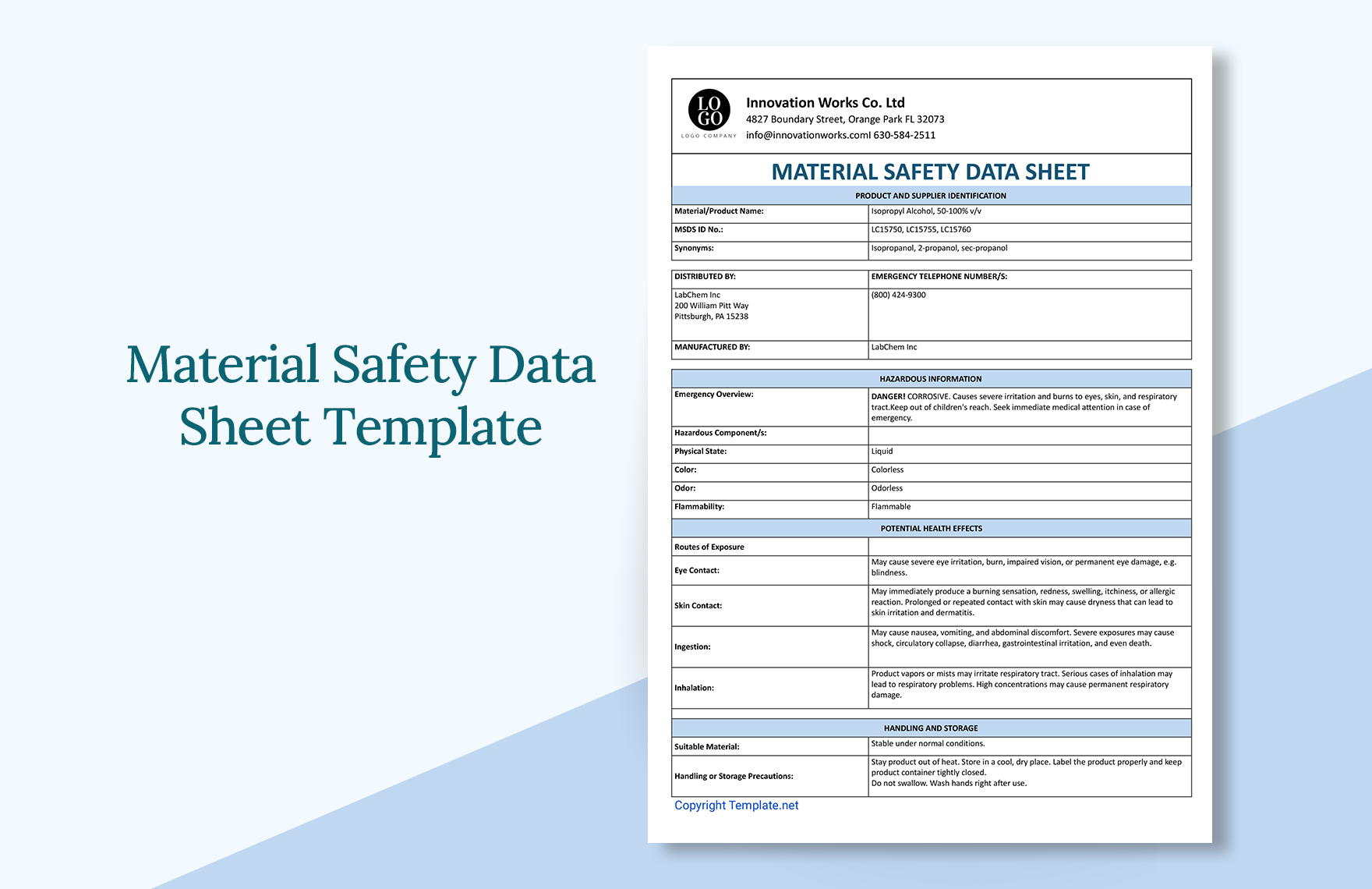

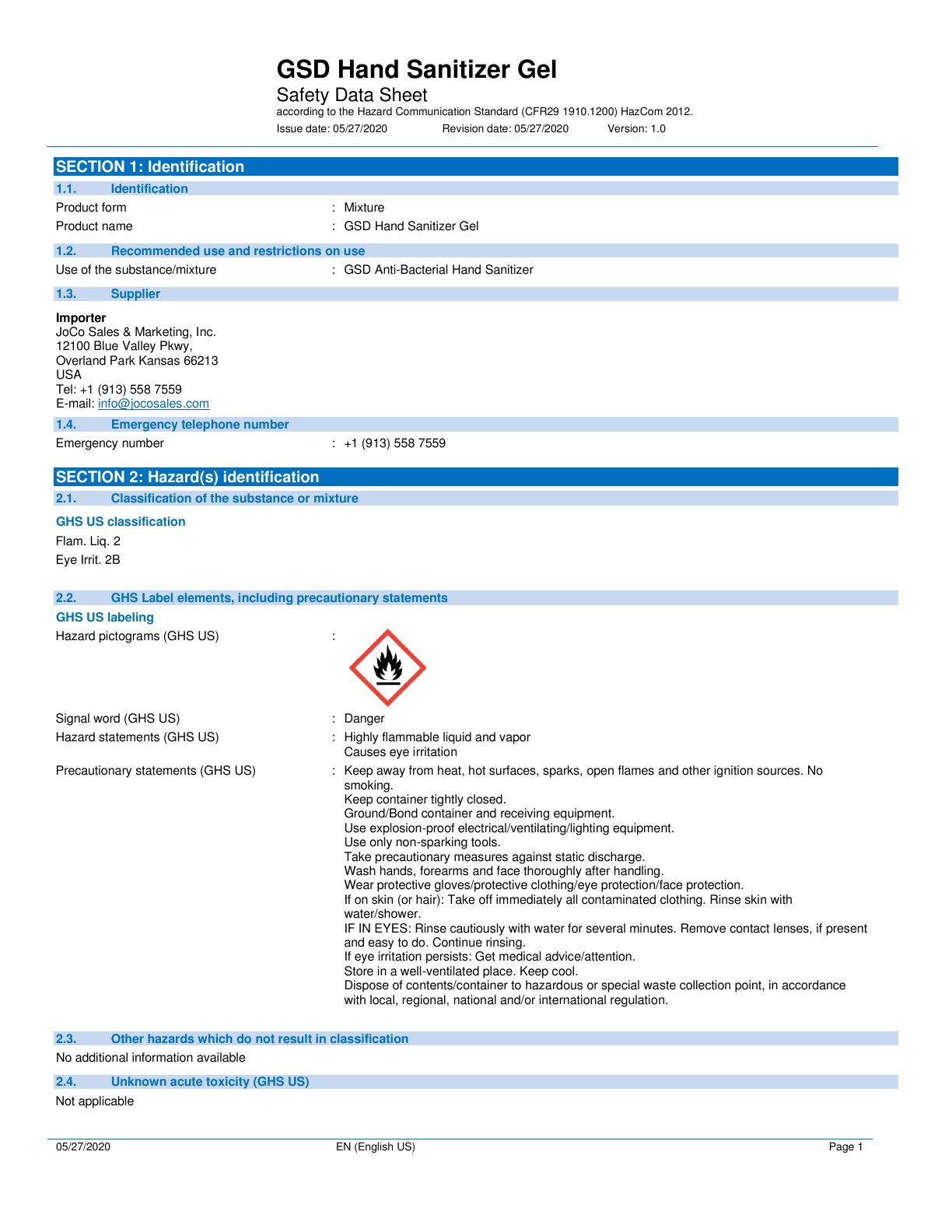

Material Safety Data Sheet (MSDS) DocsLib

The information provided in this material safety data sheet has been based upon the current level of information available, for the purpose of. This msds only provides information on the safety of the product for those who have received the appropriate professional training for the. Hazard data contained herein was obtained from raw material suppliers. Safety data sheet version 6.8.

Example of Material Safety Data Sheet (MSDS) Free and customisable

This msds only provides information on the safety of the product for those who have received the appropriate professional training for the. Under normal conditions of use, this product is not expected to create any. The information provided in this material safety data sheet has been based upon the current level of information available, for the purpose of. Identification 1.1.

Technical Data Sheet (Polypropylene)

This msds only provides information on the safety of the product for those who have received the appropriate professional training for the. Identification 1.1 product identifiers product. Safety data sheet version 6.8 revision date 05/05/2025 print date 05/06/2025 section 1. This material is classified as not hazardous under osha regulations. Hazard data contained herein was obtained from raw material suppliers.

Material Safety Data Sheet Template Free Doctemplates Vrogue

This msds only provides information on the safety of the product for those who have received the appropriate professional training for the. Identification 1.1 product identifiers product. Additives have been incorporated to stabilize the polymer in appropriate amount according to specification of particular grade of. The information set forth herein has been gathered from standard reference materials and/or supplier test.

Safety Data Sheet For Bath And Body Works Lotion at Amy Beck blog

This material is classified as not hazardous under osha regulations. The information provided in this material safety data sheet has been based upon the current level of information available, for the purpose of. Safety data sheet version 6.8 revision date 05/05/2025 print date 05/06/2025 section 1. This msds only provides information on the safety of the product for those who.

(PDF) Product Data Sheet Polypropylene RA130E Borouge Files/PPandPER

Safety data sheet version 6.8 revision date 05/05/2025 print date 05/06/2025 section 1. This material is classified as not hazardous under osha regulations. Additives have been incorporated to stabilize the polymer in appropriate amount according to specification of particular grade of. The information presented is believed to be factual, as it was derived from. Hazard data contained herein was obtained.

Material Safety Datasheet HIT RE 100 en Material Safety Datasheet IBD

Identification 1.1 product identifiers product. This msds only provides information on the safety of the product for those who have received the appropriate professional training for the. Hazard data contained herein was obtained from raw material suppliers. Additives have been incorporated to stabilize the polymer in appropriate amount according to specification of particular grade of. Safety data sheet version 6.8.

Osha Msds Printable Sheets

Identification 1.1 product identifiers product. The information provided in this material safety data sheet has been based upon the current level of information available, for the purpose of. Additives have been incorporated to stabilize the polymer in appropriate amount according to specification of particular grade of. This material is classified as not hazardous under osha regulations. Under normal conditions of.

How To Bid A Spray Foam Insulation Job Oak Ridge

Additives have been incorporated to stabilize the polymer in appropriate amount according to specification of particular grade of. Safety data sheet version 6.8 revision date 05/05/2025 print date 05/06/2025 section 1. The information set forth herein has been gathered from standard reference materials and/or supplier test data and is to the best knowledge and. Hazard data contained herein was obtained.

This Material Is Classified As Not Hazardous Under Osha Regulations.

The information provided in this material safety data sheet has been based upon the current level of information available, for the purpose of. The information set forth herein has been gathered from standard reference materials and/or supplier test data and is to the best knowledge and. Safety data sheet version 6.8 revision date 05/05/2025 print date 05/06/2025 section 1. Hazard data contained herein was obtained from raw material suppliers.

This Msds Only Provides Information On The Safety Of The Product For Those Who Have Received The Appropriate Professional Training For The.

Additives have been incorporated to stabilize the polymer in appropriate amount according to specification of particular grade of. Under normal conditions of use, this product is not expected to create any. The information presented is believed to be factual, as it was derived from. Identification 1.1 product identifiers product.